Hydraulic suspension, a cutting-edge technology, enhances vehicle control and stability through pressurized fluid. Key components include cylinders converting pressure to motion, pumps generating high-pressure fluid, and switches managing fluid flow for precise adjustments. This system offers improved handling, safety features, and customizable ride characteristics, adapting to various driving conditions from off-road terrain to on-road transitions. Its precision control benefits braking, intake, and exhaust components, contributing to overall vehicle performance and stability.

Hydraulic suspension systems are a complex yet crucial component of modern vehicles, offering precision control and superior ride quality. This article delves into the intricacies of hydraulic suspension, focusing on its key components—cylinders, pumps, and switches—and how they work in harmony to enhance vehicle performance and comfort. Understanding these fundamental elements is essential for anyone interested in automotive engineering and the ongoing evolution of hydraulic suspension technology.

- Understanding Hydraulic Suspension Basics

- Key Components: Cylinders, Pumps, and Switches

- How These Parts Work Together in Harmony

Understanding Hydraulic Suspension Basics

Hydraulic suspension is a sophisticated system that utilizes pressurized fluid to provide vehicle control and stability. At its core, this technology hinges on three key components: cylinders, pumps, and switches. Cylinders act as the force multipliers, converting hydraulic pressure into linear motion, enabling smooth adjustments in ride height or active suspension dynamics. Pumps are responsible for generating and maintaining this high-pressure fluid, delivering it precisely where needed to control various vehicle systems. Switches, acting as the command center, govern the flow of fluid, allowing for real-time adjustments to suit different driving conditions.

This advanced system offers numerous advantages, such as enhanced handling, improved safety features, and customizable ride characteristics. For instance, in off-road vehicles, hydraulic suspension can adapt to rugged terrain by adjusting clearance, while on the road, it ensures a comfortable ride through rapid changes in speed and surface conditions. Components like brake rotors, air intake systems, and exhaust tips can all benefit from this technology’s precision control, contributing to overall vehicle performance and stability.

Key Components: Cylinders, Pumps, and Switches

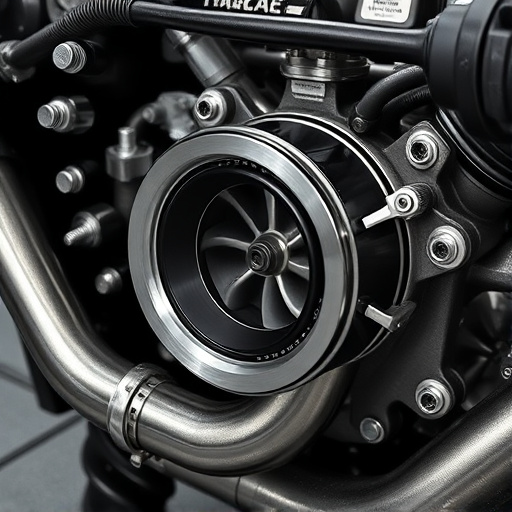

The heart of any hydraulic suspension system lies in its three key components: cylinders, pumps, and switches. Cylinders are responsible for converting hydraulic fluid pressure into mechanical movement, enabling smooth and controlled adjustments to the vehicle’s height or ride characteristics. These components come in various types, including single-stage and double-stage designs, each offering different performance advantages.

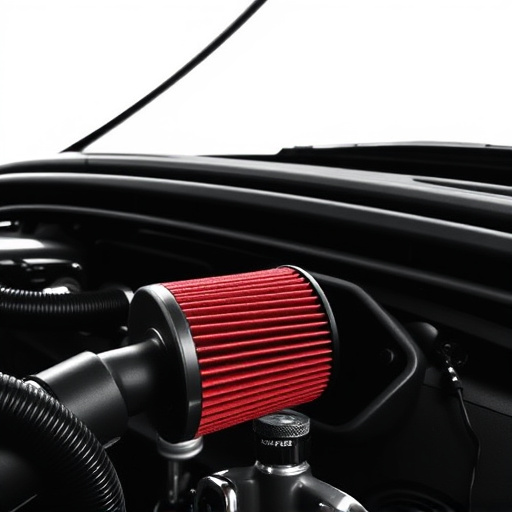

Pumps play a crucial role in generating the high-pressure hydraulic fluid that powers the system. They can be powered by various sources, such as electric motors or engine-driven pumps, with some advanced systems utilizing multiple pumps for enhanced control and efficiency. Switches act as the control center, allowing drivers to easily adjust the suspension settings according to their preferences, whether it’s for optimal driving dynamics or comfort. Upgrading these components with performance air filters and air filter kits can significantly improve the overall performance and longevity of a hydraulic suspension system.

How These Parts Work Together in Harmony

The heart of any hydraulic suspension system lies in its seamless integration of cylinders, pumps, and switches. These components work together like a well-choreographed dance, ensuring smooth and controlled movement. Cylinders, acting as the muscular force behind the suspension, expand and contract based on the pump’s delivery of pressurized fluid. This action raises or lowers the vehicle, allowing for precise control over ride height and comfort.

The pump, often powered by the engine, generates the necessary hydraulic pressure, pushing fluid through lines to each cylinder. Switches play a crucial role in this process, governing the flow of fluid and thereby directing the suspension’s behavior. Together, they create a dynamic system that not only enhances vehicle dynamics but also contributes to overall driving experience, especially when paired with high-quality cat back exhaust and exhaust systems. This integrated approach ensures that every journey is smooth, stable, and tailored to the driver’s preferences.

Hydraulic suspension systems, with their core components of cylinders, pumps, and switches, offer unparalleled control and precision. By understanding how these elements work in tandem, vehicle manufacturers can optimize performance, ensuring a smoother ride and enhanced handling. This knowledge is pivotal in the ongoing evolution of automotive technology, solidifying hydraulic suspension as a key innovation that continues to shape the future of transportation.