Hydraulic suspension systems leverage fluid pressure to control and adjust vehicle parts, offering superior ride quality and handling. Key components include pumps, valves, cylinders, and reservoirs, enabling pistons to manipulate springs and dampeners. Advantages include rapid compression and rebound abilities, enhancing performance, comfort, and stability. Widely used in automobiles, industrial machinery, construction equipment, and aerospace systems for improved safety and handling on various terrains.

Hydraulic suspension systems, with their remarkable ability to achieve fast compression and rebound, have revolutionized various industries. This advanced technology harnesses the power of hydraulics to provide precise control over vehicle dynamics, offering enhanced performance and comfort. In this article, we’ll explore the fundamental principles of hydraulic suspension, uncover its key advantages, and delve into diverse applications across different sectors, highlighting the multifaceted benefits it brings.

- Understanding Hydraulic Suspension Basics

- Advantages of Fast Compression and Rebound

- Applications and Benefits in Various Industries

Understanding Hydraulic Suspension Basics

Hydraulic suspension systems are a complex yet ingenious engineering marvel designed to revolutionize vehicle dynamics. At its core, hydraulic suspension utilizes fluid pressure to control and adjust the position of various parts, enabling precise control over ride quality and handling. This system consists of several key components: pumps, valves, cylinders, and reservoirs. The basic principle involves using pressurized fluid to move pistons inside cylinders, which in turn manipulates the vehicle’s springs and dampeners.

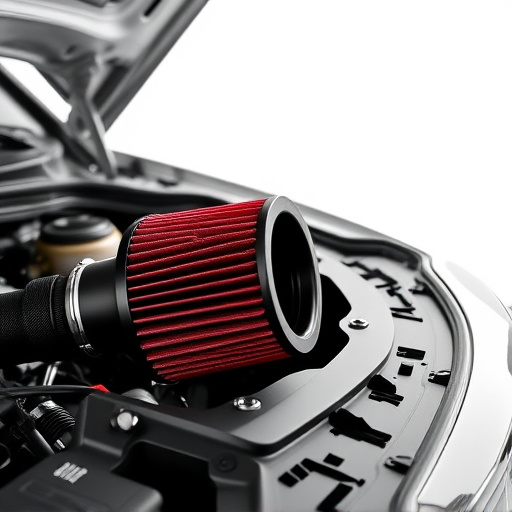

This technology offers significant advantages in terms of performance and comfort. For example, when a vehicle encounters an obstacle like a pothole, the hydraulic suspension can quickly compress and rebound, minimizing the impact on passengers. Moreover, it allows for precise tuning, making it popular among car enthusiasts who install coilover kits for enhanced control and stability. Additionally, high-performance air filters in these systems ensure optimal fluid flow, contributing to better overall performance and longevity of brake components.

Advantages of Fast Compression and Rebound

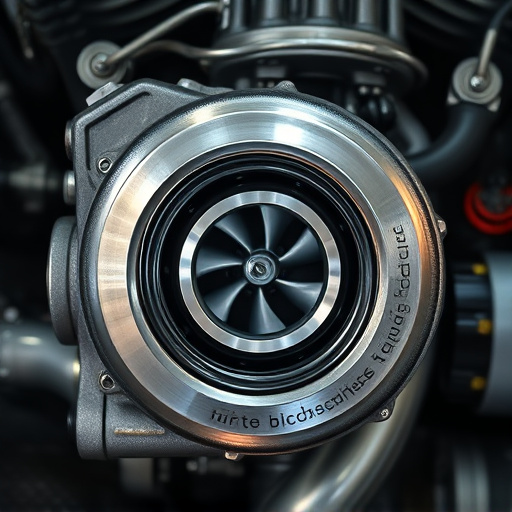

The advantages of a hydraulic suspension system’s fast compression and rebound capabilities are significant, particularly for vehicle performance enthusiasts. This technology allows for precise control over the vehicle’s movement, ensuring a smoother yet more responsive ride. During acceleration or when navigating winding roads, the quick compression enables the suspension to absorb impacts efficiently, reducing body roll and enhancing handling. As a result, drivers experience better control and stability, especially in challenging driving conditions.

Moreover, fast rebound helps maintain optimal tire contact with the road surface, which is crucial for improved grip and traction. This feature is beneficial when traversing rough terrain or making sudden maneuvers, as it enables the vehicle to respond swiftly to driver inputs. The seamless integration of these processes also contributes to reduced fatigue on both the suspension components and the driver, ensuring a more enjoyable and comfortable driving experience overall, especially with the added performance potential for exhaust mufflers and coilover kits.

Applications and Benefits in Various Industries

The versatility of hydraulic suspension is a cornerstone of its widespread adoption across numerous industries. Its ability to achieve rapid compression and rebound makes it an ideal solution for applications demanding precise control and responsiveness. In automotive sectors, for instance, hydraulic suspensions enhance vehicle stability and handling, particularly in rugged terrains or during high-performance driving. This feature translates into improved safety and driver confidence.

Beyond the automotive realm, hydraulic suspension technologies find utility in industrial machinery, construction equipment, and even aerospace systems. In industries involving heavy machinery, such as manufacturing plants and construction sites, these suspensions contribute to smoother operations by mitigating shock loads on sensitive components like brake systems and exhaust systems. Moreover, their adaptability allows for customized setups, catering to specific requirements of various vehicles and machines, including those equipped with performance brakes.

Hydraulic suspension systems, renowned for their fast compression and rebound capabilities, offer unparalleled performance across diverse industries. By leveraging fluid power, these suspensions provide precise control, enhancing both comfort and stability in various applications. Whether in automotive, construction, or industrial machinery, the advantages of hydraulic suspension are clear: improved ride quality, increased maneuverability, and reduced maintenance needs. Understanding and harnessing these benefits can significantly elevate performance and efficiency in today’s demanding environments.